Introduction

The Drillbotics competition is a prestigious global event organized by the Drilling Systems Automation Technical Section (DSATS) of the Society of Petroleum Engineers (SPE). It attracts universities from around the world, aiming to expand and accelerate Research, Development and Deployment (RD&D) activities in drilling automation. This global competition attracts university Drillbotics teams from North America, South America, Europe, Africa, Middle East, Asia, etc.

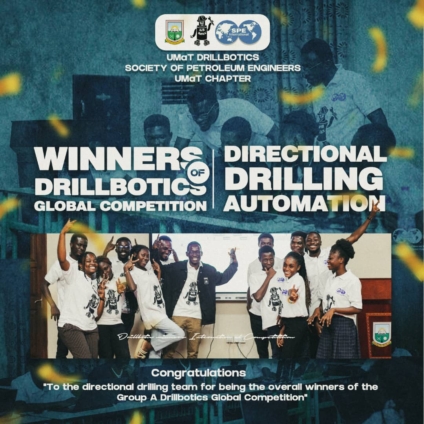

The UMaT Drillbotics team achieved outstanding success, emerging as the overall winners in the Directional Drilling Automation (Group A – Virtual Rig) competition. This victory highlights UMaT intense focus on Petroleum engineering education, also the commitment to produce industry ready graduates for the industry. This success also establishes UMaT as a global force in Drilling Engineering Research and Directional Drilling Automation.

Project Overview

The project centered on the creation of advanced software to automate directional drilling. The UMaT drillbotics team developed a software that allows users to plan and automate the drilling process, while ensuring achievement of planned trajectories, with good wellbore quality and placement. The software also has automated anti-collision technologies, requirements that are deemed critical for efficient and safe construction of close-proximity wells within a field. The software's applicability spans from the planning phase to the execution phase of drilling projects, highlighting a significant milestone achievement by the UMaT team. The project, as executed, was carried out in two phases - Phase I and Phase II.

Phase I: Conceptual Design

In the initial phase of the \project, the team focused on the conceptual design framework of the automated drilling system. This phase was critical in laying the groundwork for the final configuration and deployment of the system. The key pillars and accomplishments included the following:

- Software Architecture Design: Devised a scalable and reliable framework for the software, ensuring it could handle the complexity of real-world drilling operations.

- Prototyping: The team created a prototype of a user-friendly interface, with emphasis on a visual foundation, that highlighted the software’s ultimate functionality.

- Collision Prevention Algorithm: Implemented an innovative algorithm capable of accurately predicting potential collisions between wells, which is vital for the safe execution of drilling programs, especially when dealing with close-proximity wells in a field.

Phase II: Detailed Design and Implementation

Building upon the solid foundation laid in Phase I, the second phase of the project focused on the detailed design and implementation of the system. Major accomplishments included:

- Automated Drilling Features: The core functionality of the software was brought to fruition, allowing users to automate the plan and execute directional drilling operations with a higher degree of precision. Additionally, the software accommodates sensitivity analysis, enabling selection of appropriate trajectories that, with regards to wellbore tortuosity and placement. The software provides real-time feedback on drilling performance, focusing on parameter requirements and trends.

- Enhanced Collision Prevention: The collision prevention algorithm was refined and subjected to rigorous testing to ensure its reliability and efficiency.

Conclusion

Winning the 2023/2024 SPE Drillbotics competition is a significant achievement that reflects the hard work, dedication, and ingenuity of the UMaT Drillbotics team. The team’s software for automated directional drilling, which won this prestigious global competition in directional drilling automation, sets the stage for more advanced and pioneering work in automation and autonomous drilling. The team is immensely proud of its accomplishments and remains strongly committed to more innovative work, and impactful contributions to the drilling industry.

Latest Stories

-

US judge halts deportation of Turkish student at Tufts

11 minutes -

US FAA to investigate close call between Delta flight and Air Force jet

30 minutes -

US judge temporarily blocks Trump from firing Voice of America staff

42 minutes -

Shi’ite protesters clash with Nigerian military, police in Abuja

54 minutes -

2Face’s new love, Natasha Osawaru adds ‘Idibia’ to name on IG

1 hour -

West African juntas impose levy on imported goods

1 hour -

Deputy Education Minister praises TTU for inclusivity

2 hours -

Trump wants India to buy US corn – but here’s why it probably won’t

2 hours -

Sky Train Scandal: ‘PAC recommended prosecution, but nothing happened’ – Avedzi

2 hours -

‘PAC exposes corruption, but the executive lets them go free’ – Avedzi

2 hours -

‘They face live TV cameras, but not justice’ – Avedzi on lack PAC of prosecution

3 hours -

The Great ECG Container Heist: A Comedy of Errors

3 hours -

Re: Petition against Justice Gabriel Scott Pwamang JSC

4 hours -

Starmer and Trump discuss ‘productive negotiations’ on economic deal

6 hours -

Star players make step up, says Guardiola

6 hours